Like most 88-year-olds, Wayne Quinton has had his share of health problems. Over the last 10 years, he has endured an aggressive prostate cancer and a course of radiation therapy, a vertebra injury and, most recently, a bad case of pneumonia. But Quinton seems to be in good health, and good spirits, these days. Several times a week he makes his way to an exercise room in his beautiful Seattle Highlands home to walk on the treadmill he invented.

Quinton is a transformative figure in the world of medicine—a status he achieved not with advanced degrees and high-profile appointments, but with the kind of determination he is now using to confront the vagaries of old age. “He’s stubborn,” says Yongmin Kim, professor and former chair of bioengineering at the University of Washington. “But very persevering and very systematic. He tries to tackle the problem, rather than bypassing it.”

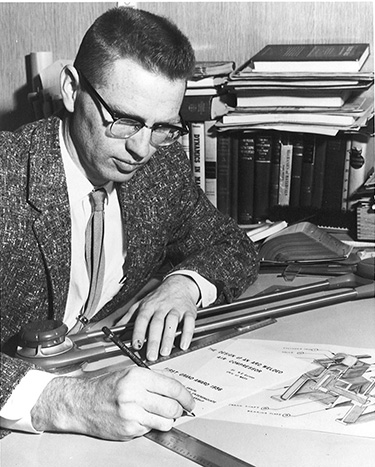

It’s a quality that helped propel Quinton from small-town Rigby, Idaho, to big-time Boeing, where he landed one week after the attack on Pearl Harbor to work on the B-29 bomber, to the University of Washington medical school, where he not only designed a laundry list of life-saving medical devices, but became the first practitioner of an entirely new field: bioengineering. “I was not afraid to say, ‘I don’t know,’” Quinton says. “And I kept asking the question, ‘Why?’”

For his prolific, groundbreaking work as instrument designer for the UW’s medical school, and for his singular role in marrying the fields of engineering and medicine, Wayne Quinton, ‘59, has been named the University of Washington’s 2009 Alumnus Summa Laude Dignatus-the “alumnus worthy of the highest praise.” He is the 69th recipient of this honor, the foremost that the UW can confer upon a graduate.

For his prolific, groundbreaking work as instrument designer for the UW’s medical school, and for his singular role in marrying the fields of engineering and medicine, Wayne Quinton, ‘59, has been named the University of Washington’s 2009 Alumnus Summa Laude Dignatus-the “alumnus worthy of the highest praise.” He is the 69th recipient of this honor, the foremost that the UW can confer upon a graduate.

It wasn’t the most likely of career trajectories for a child born to Depression-era Idaho farmers. But Quinton always showed a mechanical aptitude, and a natural curiosity about how things worked. When he was a little boy, he spent weeks deconstructing and reassembling the metal toys he got for Christmas. He worked over one wind-up Model T car so often it got metal fatigue. So he taught himself how to solder, then repaired it.

When he was in high school, his father suffered a heart attack and was ordered to years of bed rest—an event that not only fired Quinton’s lifelong interest in medicine but elevated his mechanical work from a hobby to a practical necessity. He fashioned a mini-plow for the family Buick so he could navigate Idaho’s wintertime roads as he drove his mother every morning to the dry-cleaning plant she owned. Soon, he could press pants with the best of them and repair any piece of equipment on the plant floor.

After graduating Rigby High with science honors in 1939, Quinton attended Ricks College (later renamed Brigham Young University) for one year, studying mathematics and engineering drafting, before transferring to Montana State College to take engineering physics courses. After only a year, however, he grew restless with college life and decided to return home to help his mother expand her dry cleaning business. This turned out to be a propitious move.

***

Archival photos of Wayne Quinton and Quinton Instruments courtesy of Cardiac Science Corporation.

It was early December 1941 when Boeing, which was recruiting throughout Idaho for technical talent, came to Rigby, and Quinton found his calling. He was immediately hired as a master-layout draftsman for Boeing’s B-29 bomber. The job paid 69 cents an hour for a 10-hour-a-day, seven-day-a-week schedule, and the enterprising Idahoan made the most of his time. He managed to pursue an informal continuing-education program by hopscotching through as many departments as possible. In Boeing’s tool planning group, Quinton found a rich training ground indeed.

He absorbed more valuable on-the-job tutoring from physicists and theoretical mathematicians while working as a draftsman on the aerospace company’s first guided missile. “It was a bunch of really smart guys with multiple Ph.D.s,” he recalls, “who were supposed to do things that the ordinary engineering people couldn’t.”

Quinton resigned from Boeing in 1948 and returned to Idaho to help his aging mother. But after a short time he determined that “being a dry cleaner was not for me” and that she was too old to continue working. They sold the plant, and Quinton returned to Seattle in 1949, where he got his first job at the University of Washington as an electronics technician. His improbable charge: to develop heat-measuring equipment for an Arctic acclimatization study. “I don’t know exactly how I managed to get that job; I was totally unqualified,” says Quinton, who at the time was still lacking a college degree. When the study ended two years later, however, the always-assertive Quinton applied for and was hired to head the medical school’s brand new instrument shop.

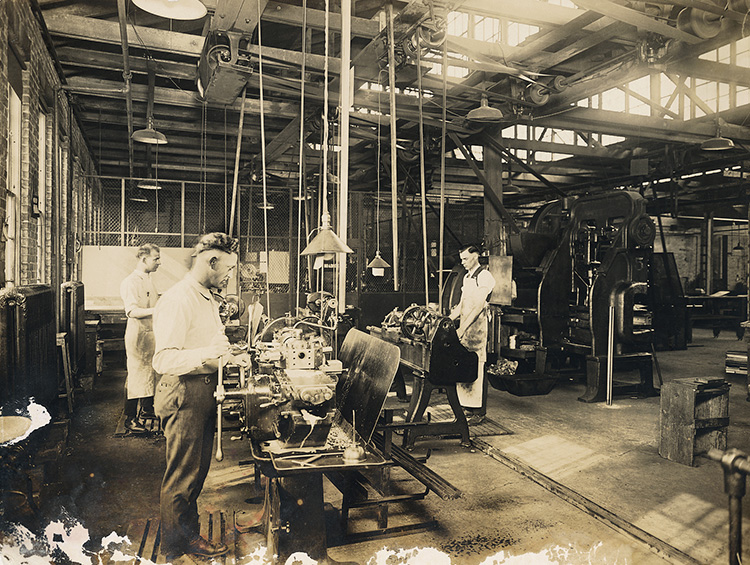

“My job description was to keep everything in the instrument field functional and to build anything they couldn’t buy,” says Quinton. “They had a space of 300 to 400 square feet and they provided me with enough money to equip this area with whatever I thought was necessary to be able to make all these gadgets.” Over the next 10 years, Quinton more than lived up to his selection in 1950 by Life magazine as one of the nation’s “25 Top Young Scientists.” He designed some 40 gadgets for the UW, from a hydraulic gastrointestinal tract biopsy device, which acted “like a choke-wire on a car” and was inspired by Quinton’s recollection of the method for mining tungsten, to a one-of-a-kind bubble oxygenator that enabled the first open-heart surgery in the Pacific Northwest (performed by the UW’s own K. Alvin Merendino).

One of Quinton’s most pioneering contributions was a shunt he co-designed with UW physicians Belding Scribner and David Dillard that allowed kidney patients to be easily reconnected to dialysis machines. Quinton came up with the idea of connecting the artery and vein catheters to allow continuous blood flow during dialysis, thereby preventing the blood from clotting. “The importance of the reliable Quinton-Scribner shunt is enormous,” Willem J. Kolff, inventor of the artificial kidney, has written. “I cannot name any small practical device that has had a greater impact. Hundreds of thousands of patients have benefited from it.”

***

During his tenure in the instrument shop, Quinton also found time to earn a mechanical engineering degree from the UW in 1959, and to launch a business in his basement. He presciently parlayed many of his medical devices that the UW declined to manufacture—and which were in great demand by physicians around the world—into Quinton Instruments. The business, relocated to Bothell, ultimately employed 700 people and was bringing in $100 million in sales annually by the time Quinton sold it for $55 million to A.H. Robbins in 1984.

Arguably, Quinton’s most influential invention was the lightweight cardiac treadmill. Before Quinton, treadmills were too cumbersome to fit into a medical setting. His streamlined model, fitted with a two-horsepower motor, became the diagnostic standard—not only revolutionizing the approach to cardiac disease diagnosis, but also fueling the aerobic exercise boom. (Surprisingly, the UW passed on the rights to manufacture the treadmill, which became one of Quinton Instruments’ best sellers.) “I’ve been very pleased with what I did during my time at the University of Washington,” Quinton says. “I was building devices that enabled people to measure something they couldn’t measure otherwise, and that added to their ability to make accurate diagnoses.”

It was Quinton’s unprecedented, hand-in-glove collaboration with physicians that gave birth to the field of bioengineering, including the UW’s Center for Bioengineering (now a department) in 1967. Unlike many of his engineering peers, Quinton schooled himself in medicine (greatly aided by the mentoring of Stanley H. Bennett, head of the UW’s anatomy department). “He tried to understand the physiology, anatomy and the clinical practice,” says Yongmin Kim. “In the ’50s and ’60s that was very unusual. Even now that’s very difficult to do because to work with clinicians, you have to understand their world, their culture, their background, as well as engineering and science.”

Quinton credits a straightforward, unshrinking attitude for his success in bridging the worlds of engineering and medicine. “It’s really easy to get inhibited with physicians because they know everything and they speak a different language,” he says, “but I never tried to say I knew something I didn’t. And I think because I kept asking the question ‘Why?,’ I taught them a little about engineering and they taught me a little about medicine.”

As one collaborator, K. Alvin Merendino, put it, “Where patients were involved, Wayne Quinton was a contributing figure in the operating room the equal of the surgeon who wielded the knife.”

Quinton likes to tell an illustrative story from his days in the UW instrument shop: Because he wasn’t a physician, he was expected to wear a yellow coat. “But I decided, ‘Hey, I’m as good a medical instrument maker as they are physicians.’ So I got a white coat,” he says with a sly smile. “At first when I went to lunch with the physicians, I got a few looks, but it wasn’t long before I was accepted. We talked. I learned, they learned.”

Tool time

A brief list of devices designed by Wayne Quinton in the UW’s medical instrument shop:

- Structure to allow polio patients to get into a sitting position

- Movable camera boom and cart to reduce time taking autopsy photos

- Uniform bubble oxygenator for use during open-heart surgery

- Hydraulic gastrointestinal biopsy instrument

- Arterial venous shunt system for kidney dialysis patients

- Lightweight treadmill for cardiac stress testing

- Mitral valve finger knife for use during open-heart surgery

- Small aortic valve dilator for use during open-heart surgery

- High-speed machine to test fatigue in artificial heart valves

- Teflon tracheotomy plug to aid patients with paralytic polio